Light-duty warehouse shelves are a type of storage equipment specifically designed for light goods and are widely used in various warehouses and logistics centers. The following is a detailed introduction to light-duty warehouse shelves, including their structural features, material selection, installation methods, applicable scenarios and advantages, etc.

I. Structural Characteristics of Light-duty Warehouse Shelves

upright:The uprights are the main supporting components of the shelves, usually made of cold-rolled steel or hot-rolled steel, featuring high strength and stability. The cross-sectional shapes of the columns are diverse, with common ones including square tubes, round tubes, C-shaped steel, etc.

beam:The crossbeam is used to connect the columns and support the goods, and is usually made of cold-rolled steel or hot-rolled steel. The cross-sectional shapes of crossbeams commonly include H-shaped steel, channel steel, etc., which have good load-bearing capacity and bending resistance.

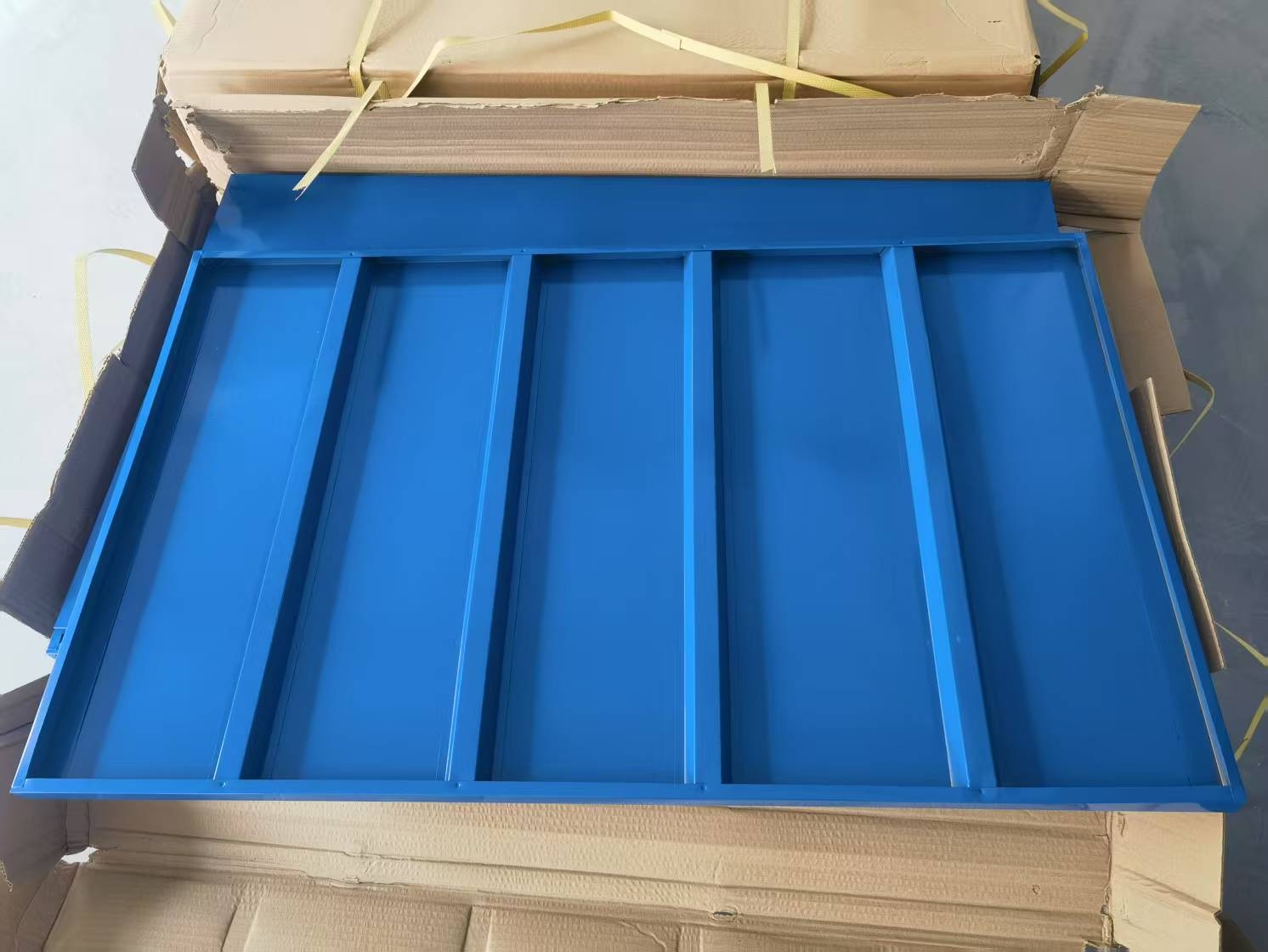

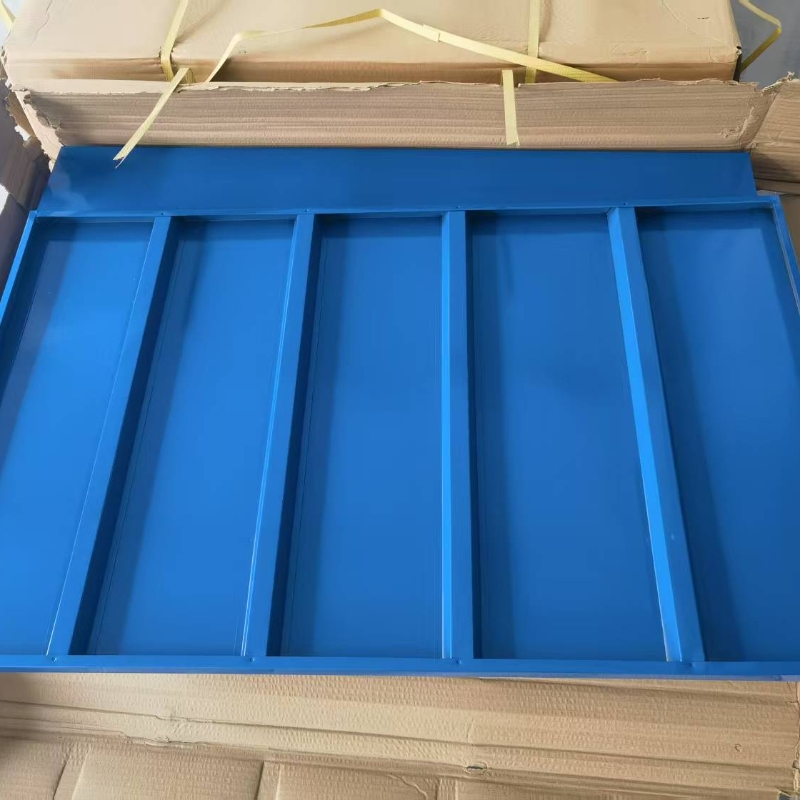

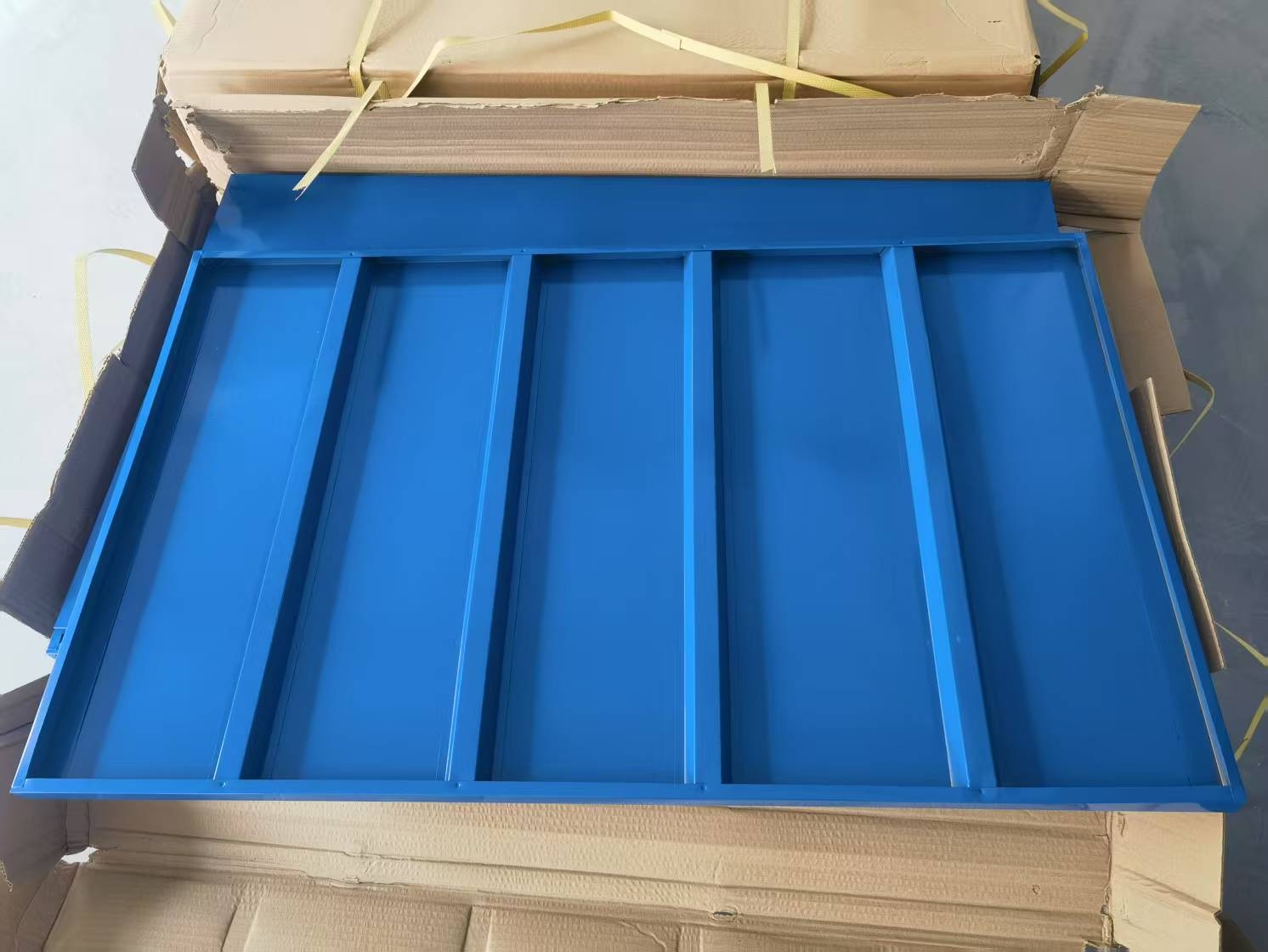

laminate:The shelves are used to directly carry goods and are usually made of cold-rolled steel plates, patterned steel plates or wooden boards. The thickness and material of the shelves are selected based on the weight and size of the goods to ensure sufficient load-bearing capacity and stability.

adapting piece:Connectors are used to fix the uprights, crossbeams and shelves, ensuring the overall structural stability of the shelves. Common connecting parts include bolts, nuts, hooks, etc.

2:Material selection for light-duty warehouse shelves

rolled steel:Cold-rolled steel: Smooth and flat surface, high strength, suitable for making the main components of shelves.

Hot-rolled steel: It has good toughness and is suitable for components that require bending processing.

Stainless steel: It has excellent corrosion resistance and is suitable for humid or chemically corrosive environments.